Running Camp Invitation for New Generation Track & Field

DCG One came to Kurblink to conceptualize an award style invitation for an upcoming camp for New Generation T&F. The customer had an initial concept of an invitation incorporating the Boulder Flatirons, as the event was set to take place in Boulder, Colorado.

Capturing the Essence

Having never been there myself, I had to rely on a range on the experience of others. Using this photo and overlaying my own trace, I did my best to capture the essence of the landscape.

Iteration makes perfect

The ability to make physical samples in addition to computer renderings, ensures the client gets exactly what they expect in the end. Here you will see a bit of the process of how it all went down.

Customer Idea

While customer submitted drawings like this lack a lot of detail, they can serve as a great leaping off point for a more detailed conversation.

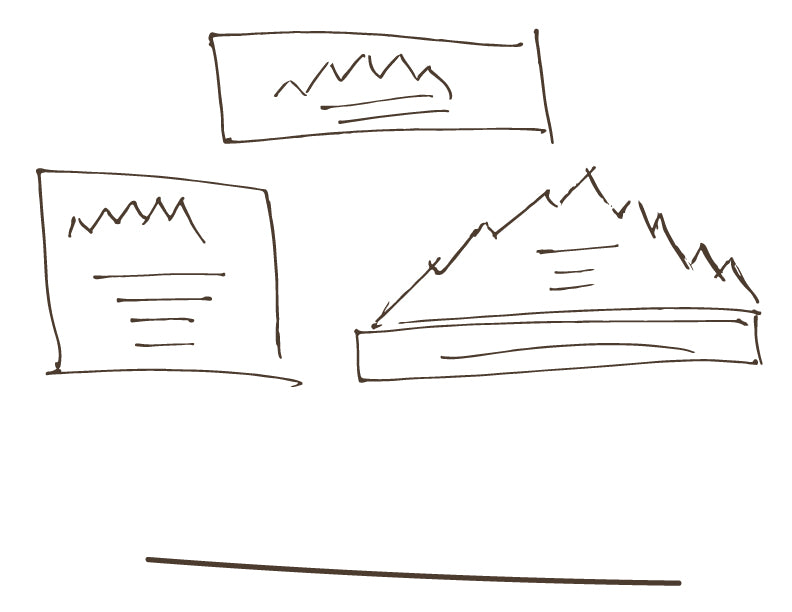

Material concept

The next step for this project was a simple mock up to see if we were on the right track. Are the materials suitable? Is the size appropriate? Where do we go from here?

Design nailed

The customer came back with some amazing feedback. It was positive, yet had some detailed guidance that really gave us insights into his vision.

- Name on the base rather than the mountains

- Make the mountains more rigid vs free flowing

- Etch the mountains on the metal

- Leave the logo on the left side of the wood base

This kind of detailed evaluation and feedback is great, because it quickly brings the project closer to completion. Once the computer rendering was completed, a physical sample to match was provided.

Base materials

Walnut was selected as the base material. Pre milled stock was used to save on production time and reduce waste.

Step one was cutting it to a rough length and milling it down further to the final profile.

Profile cut

Before the profile can be cut, the display surface must be selected. Face grain and side grain not only have different looks, they have different strength properties. Considering a metal insert would be press fit into the groove, the stresses were considered and the grooved surface was selected accordingly.

Bases engraved

The bases were engraved using a 100 Watt CO2 laser. In an attempt to achieve the darkest engrave possible, not much exhausting was used and the power was dialed up a bit. This would allow the smoke to deposit in the engraved area.

As a result, you can see there's quite a bit of resin that builds up on the surface. That will be cleaned off in the next steps.

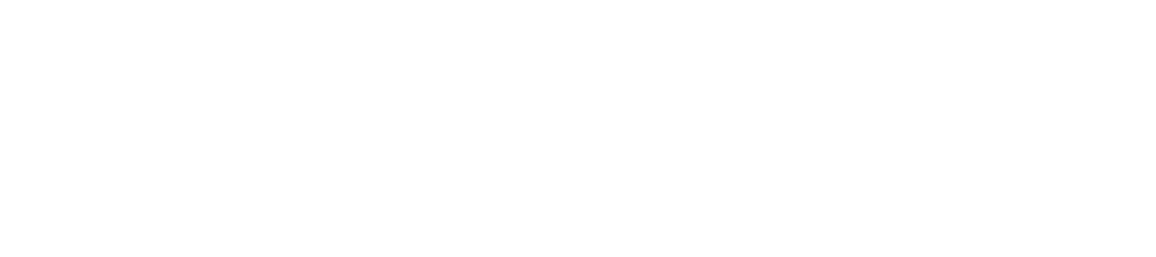

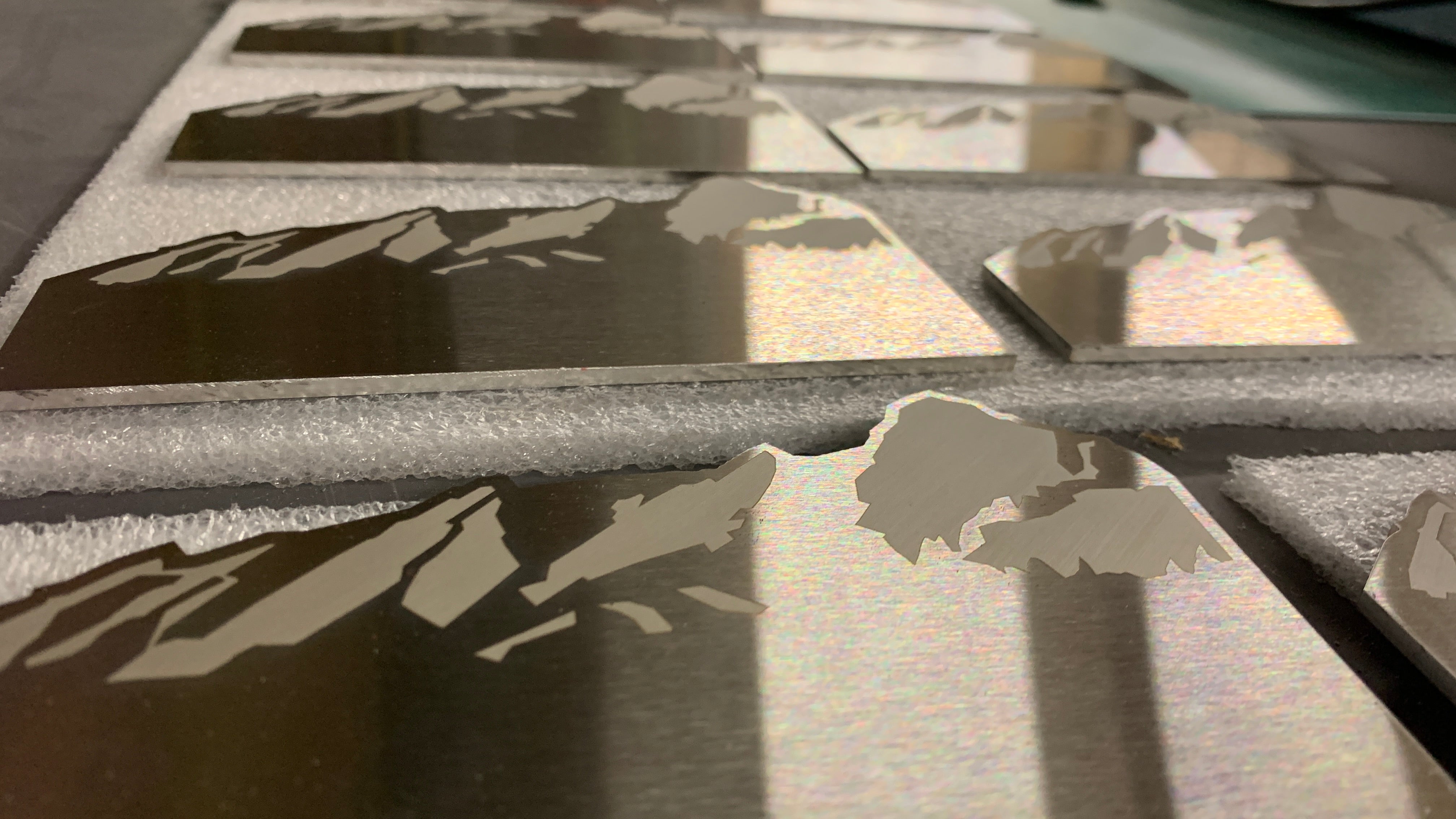

Etching

The mountains were made of laser cut stainless steel by my friends at Laserfab (where I worked previously) on their 4000 Watt CO2 laser. After dressing the edge with an abrasive Scotchbrite wheel, I etched the mountains. I used a 50 Watt fiber laser to do a light colored etch.

Black annealing

Using the same fiber laser that I used for etching the mountains, I black annealed the text below. It provides a very nice contrast and more visual interest.

Finished

The bases were sanded to remove resin from engraving and the corners were eased for a soft feel. A protective polyurethane finish was added before the mountains were fitted into the wooden bases.

This project was more complex than most due to the mix of materials. However, it was a lot of fun and I am proud of the results. What's more, I'm grateful to have had the chance to serve DCG One and their customer New Generation T&F.