What is Kurblink?

Kurblink is my fabrication business, centered around laser technology. With additional support equipment and skills in an assortment of materials, I can help you bring your project to life.

Some of the work I do requires little-to-no computer work, and I find myself in the shop most of the time. Other times, the planning and preparation is 90% of the work.

No matter what I am doing, I am happy to be serving you. Your faith in me means everything.

What makes Kurblink different?

It would be nice to say I have the biggest equipment or the most special processes. I don't. What makes Kurblink so special is the reputation I have built for quality service. I understand the challenges of being a buyer and a project manager. That insight guides me in delivering helpful, honest, and fair support for your endeavors.

Can't anyone give quality service? Absolutely, but do they? And do they do it consistently? These days I find it increasingly difficult to hold other businesses to a higher standard. Among the excuses given, "we just don't have the resources." I believe it has nothing to do with resources and everything to do with the company's priorities.

Kurblink is built to prioritize the customer. I know that if I can do that consistently, growth and profitability of my business will follow. I hope you'll trust me and agree.

Keith is professional and helpful. He worked with me closely on my project and I am very happy with his commitment and work. This will be my go-to for my future projects.

— John D.

Partial Equipment List

Here are a few of the tools I use to serve you on your endeavors.

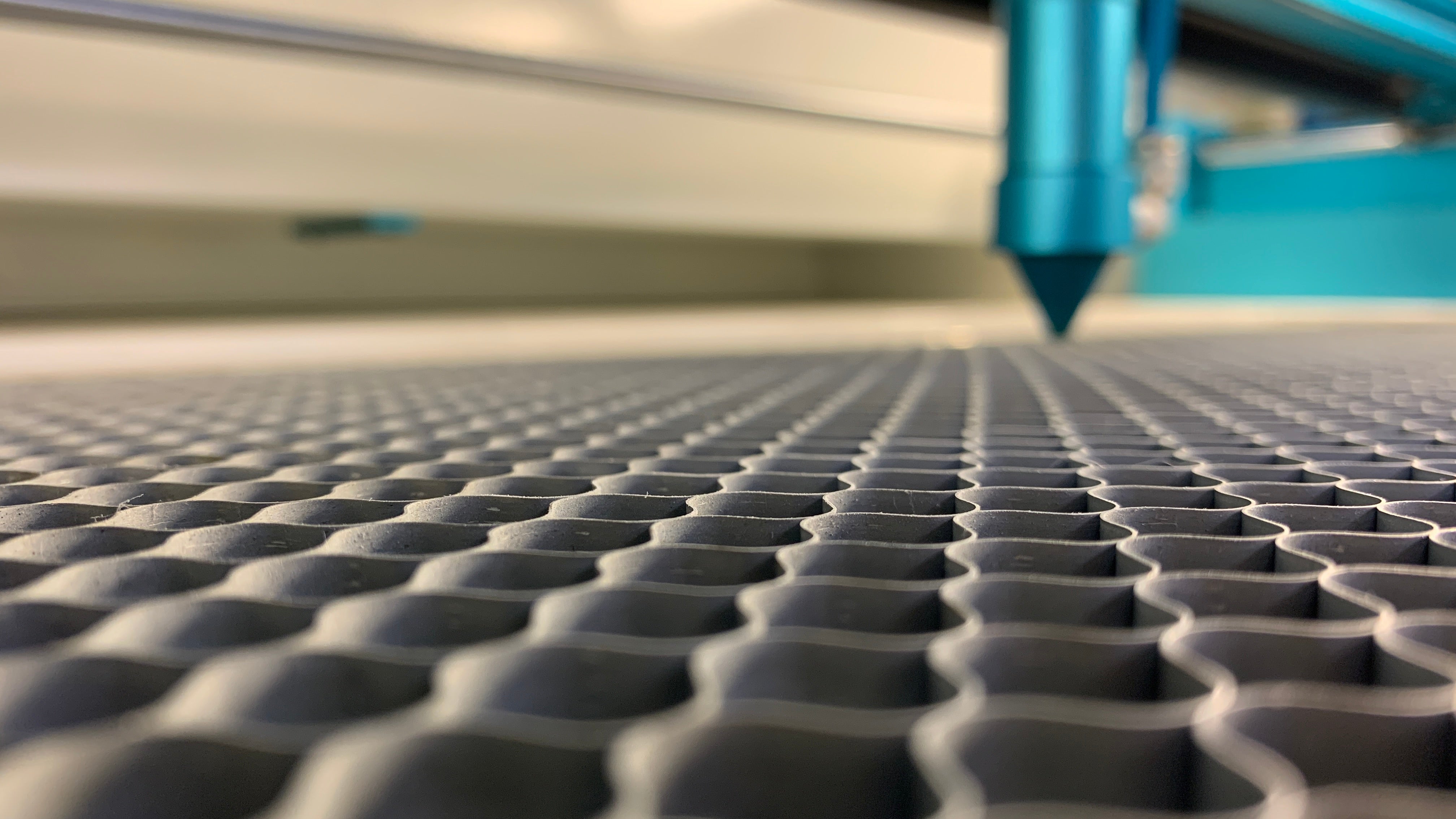

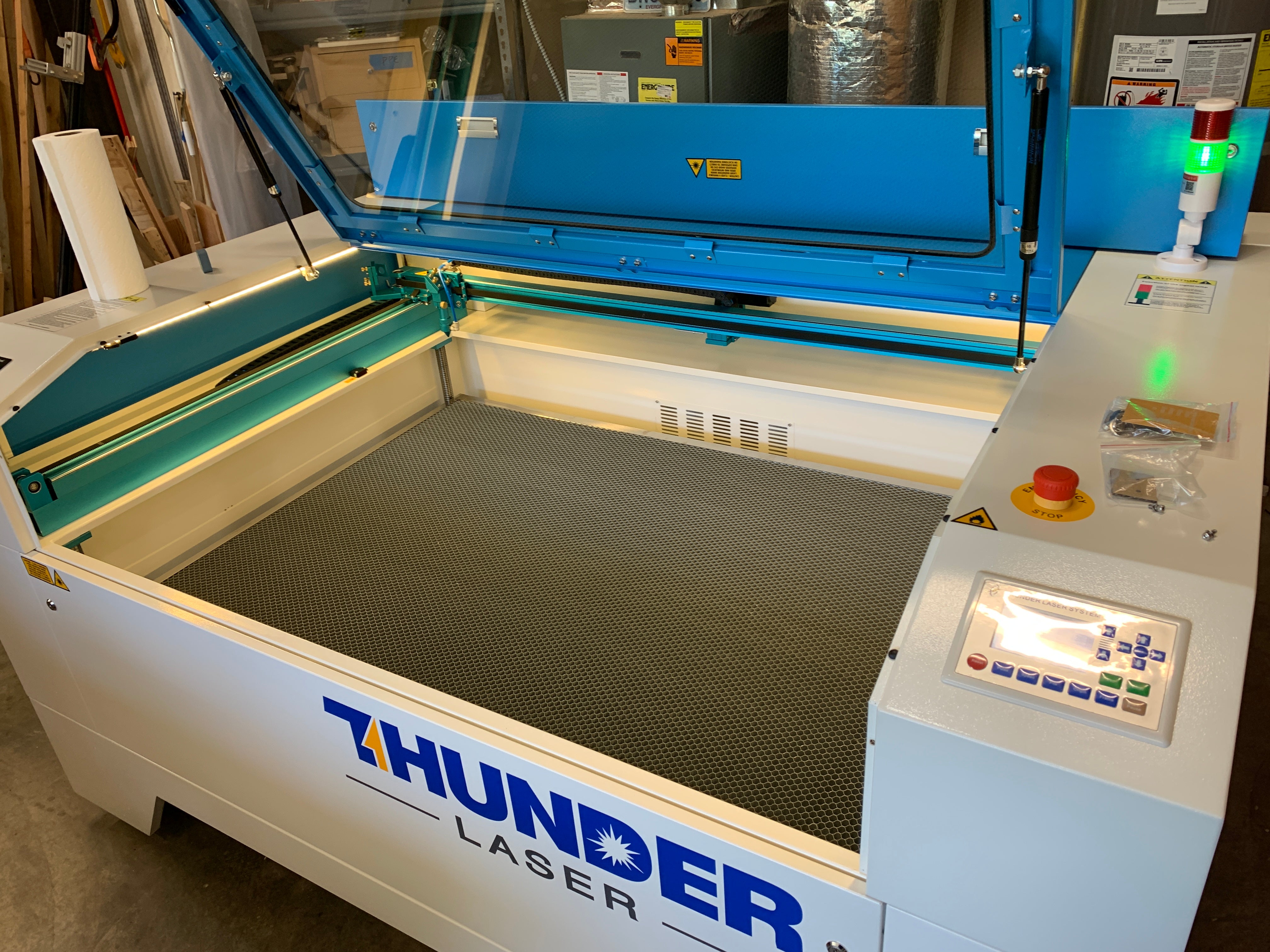

CO2 Laser

CO2 lasers work well on:

- wood - cutting & engraving

- acrylic - cutting & engraving

- slate / granite / marble - engraving

- paper - cutting & engraving

- corrugated - cutting

- fabrics - cutting

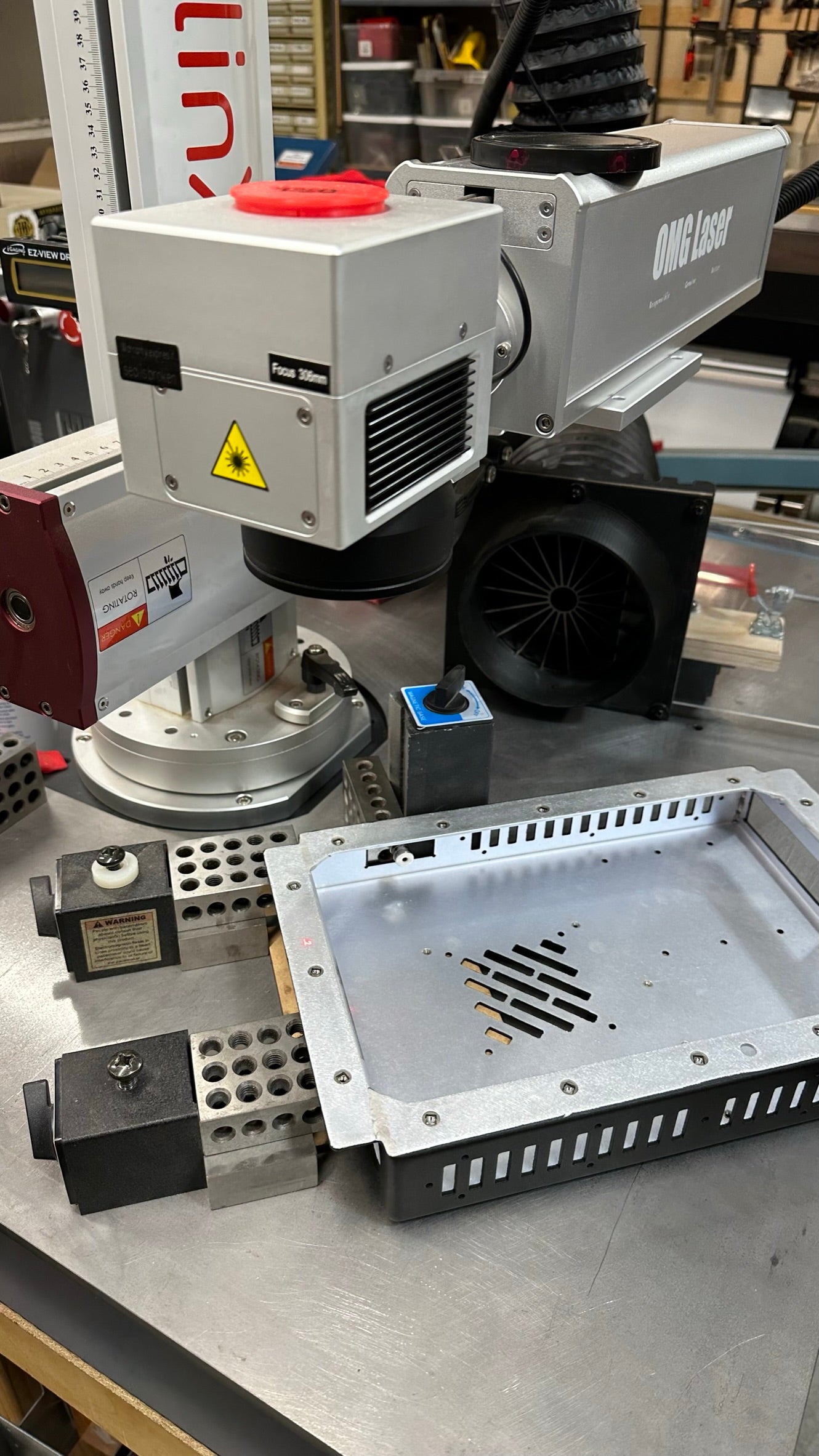

Fiber Laser

Fiber lasers work well on:

- metals - engraving, marking & cutting

- ABS - marking

- slate / granite / marble - engraving

3D Printers

3D printers are best used for tooling and for prototyping. They hold very nice tolerances and are well suited for jobs where alternatives either cost too much or take too long to produce.

Here is my smallest 3D printer in the Kurblink shop working on printing a prototype bracket that will later be produced from steel for the telecom industry.

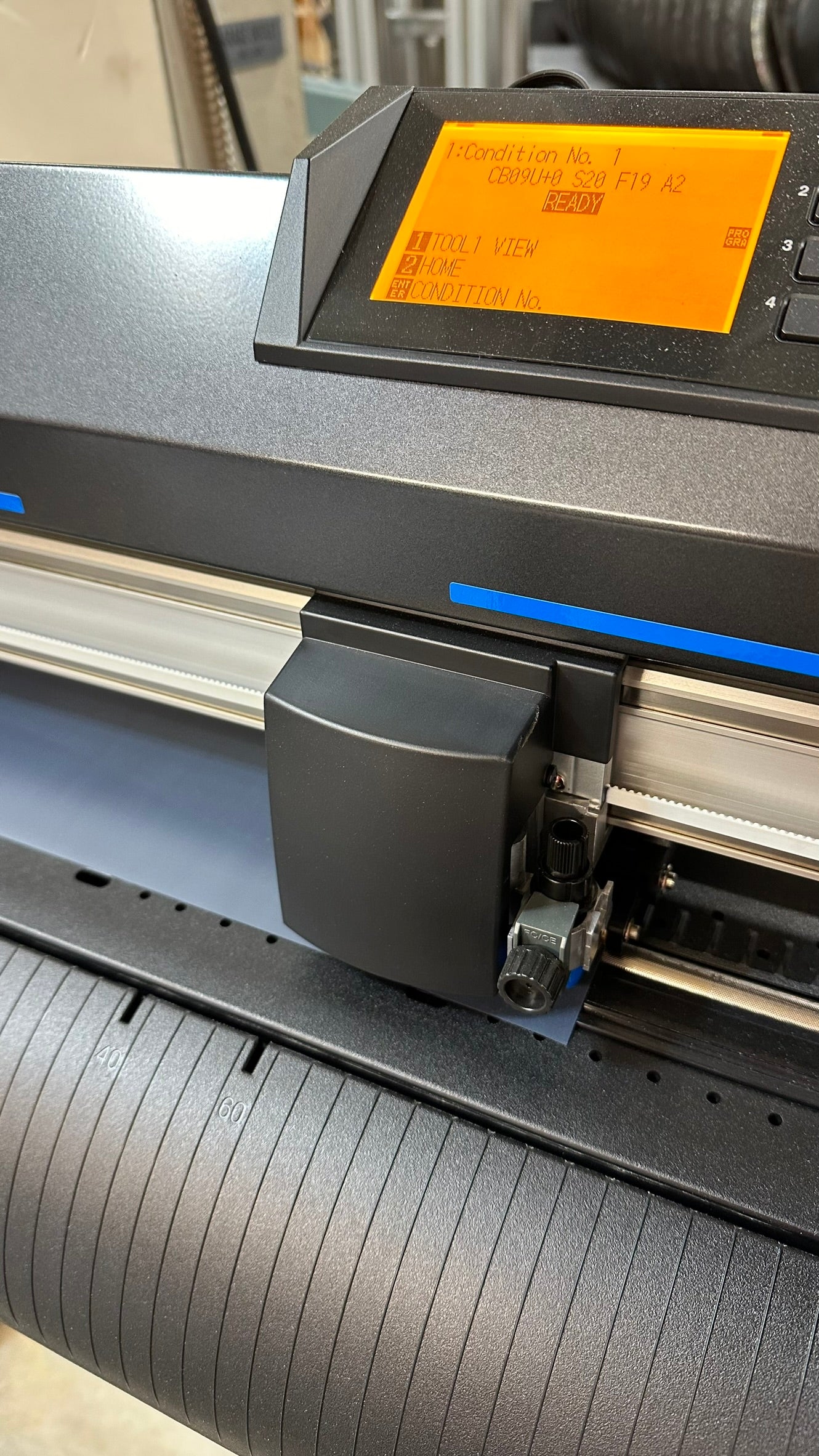

Vinyl cutter

24" Vinyl cutting machine / plotter.

Drill press

Not all the equipment used is super sexy, but a drill press is an indispensable must-have in the shop. It gets used plenty along with many other non-computerized power tools.

Here it is being used to drill large hanging holes in a spiral bound laminated set of procedures for a hospital. The original producer of the booklets missed the instructions to include large holes rather than their typical small hanging hole. It was less expense to rework the books at Kurblink.

Table saw

A work horse of any serious fabrication shop is a table saw. It was the first "major" piece of equipment I ever bought before starting Kurblink. At the time I wondered if it was a smart and justifiable purchase. Years later, it is clear that it was the most necessary purchase in the shop.

Here it is outfitted with a large sled and custom, temporary fixture for delicately trimming down 10,000 plastic binder bars. Long running job, but there is no other feasible way I could have accomplished the task.